ICAO code: FAET

ATEC 321 FAETA NG is the „next generation“ of ultralight aircraft. Taking advantage of our long-term experience and getting inspired by new ideas and experience of our customers, we designed and produced the most advanced aircraft established on the conception of original Faeta. The main noticeable difference between the original Faeta and Faeta NG is tailplanes arrangement. Tailplanes of the NG are designed in classical cross-shaped configuration. Also the shape of the dashboard is slightly modified to be able to accomodate also instruments of larger size. The instrumental board with 3D effect is made of titanium composite. So we created the combination of the latest design trends and technologies, aerodynamic purity, high performance and mainly of the safety. In addition, we focused on fashionable look of the airframe highlighted by its specific elegant curves.

The Faeta NG is certified in the UL category up to 600 kg MTOW and LSA category. Such weight limit allows us to increase a comfort of the crew. The aircraft is equipped with the system of electric „smart flaps“ and optionally by the heating of seats. Spacious, fully upholstered, well ventilated and heated cockpit provides a good view out. Seats and pedals are adjustable. A load capacity of well reachable luggage compartment is 20 kg.

To improve overall design quality of both the interior and exterior we use our 3D printer, which enables us effective production of small parts of suitable material to fit with our need. Faeta NG is now fitted with more than hundred various printed parts like bushings, covers, holders and other gadgets like e.g. drink bottle holder inbuilt in the central tunnel.

Carbon composite airframe is standardly made of aviation certified carbon twill of the highest quality. Thanks to our own original production technology, we are able to assure high strength of the construction while keeping its low weight. The aircraft does not get any flutter up to the maximal calculated speed of 550 km/h.

Aerodynamically pure design allows Faeta to reach perfect flight characteristics exceptional within its category. The aircraft is manoeuvrable, but stable and with immediate reactions of controls from its max. speed of 272 km/h (148 kt) until its extremely low stall speed of 56 km/h (30 kt).

The Faeta NG, same as other ATEC aircraft, is the best option for touring, daily flights and also for training. Its flight characteristics help to ensure safe operation, comfortable travels, low consumption (8-12 L/h) and so economical operation and long flight range.

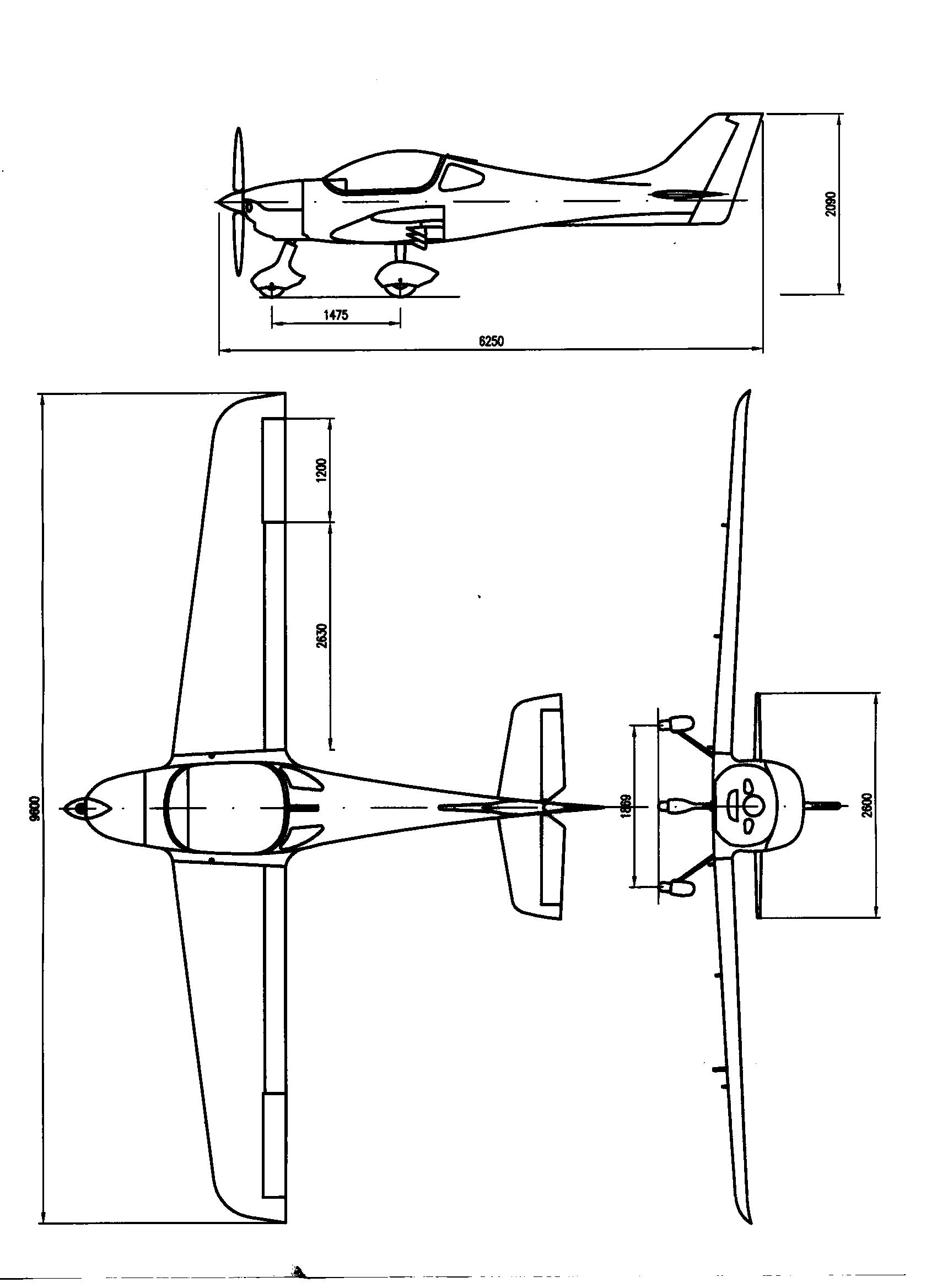

Basic characteristics

Specification (MTOW 600 kg)

| Wing span | 9,6 m |

| Length | 6,25 m |

| Height | 2,1 m |

| Wing area | 10,1 m2 |

| Tail span | 2,4 m |

| Wheel spacing | 2,0 m |

| Empty weight | 320 kg |

| Max. take-off weight | 600 kg |

| Fuel capacity | 2 x 50 L |

| Max. load in luggage compartment | 20 kg |

Performance (MTOW 600 Kg, Rotax 912 iS 100HP)

| Cruising speed VC | 242 km/h / 131 kt |

| Never exceed speed VNE | 272 km/h / 148 kt |

| Stall speed (flaps extended) VS0 | 56 km/h / 30 kt |

| Stall speed (flaps retracted) VS1 | 75 km/h / 40 kt |

| Rate of climb | 7,5 m/s / 1476 ft/min. |

| G-load limit | +4 / -2 g |

| Flight range | 2000 km |

| Consumption (180/245 km/h) | 9/14 L/h |

Technical details

ATEC 321 Faeta NG is a full-composite cantilever low-wing aircraft with the engine in pulling configuration, three-wheel landing gear, classical tailplanes and a two-seater cockpit with side-by-side seats. Whole the aircraft is designed and manufactured by us from the very beginning, i.e. from appropriate moulds, through the carbon composite to the airworthy machine. It is just carbon fiber that creates the most of its structure, and the carbon composite can guarantee its incredible strength. Did you know that 1 mm of carbon composite equals the strength of 1 cm of steel? In addition, these two materials are incomparable in weight.

For the purpose of certification for the category up to 600 kg MTOW, all parts of the aircraft had to pass the strength tests in order to comply with required resistance to the load determined by the calculations based on input value of 600 kg and the safety coefficient up to 1,875 added. The construction of Faeta NG passed all these demanding tests successfully without problems. The flutter tests did not show presence of flutter up to the maximum calculated airspeed of 550 km/h.

Wing

The wing conception is the same as it is applied on the wing of ATEC 321 FAETA. It is cantilever tapered backswept wing with an angle of 5,5° and SM 701 airfoil along the whole span. Its construction is composed of the main spar with the secondary spar in the area of ailerons. The coating is made of carbon sandwich supported by ribs made of Divinycell foam. The main spar is made of laminated hard beech wood saturated with synthetic resin - a structurally well proven material to achieve appropriate high strength and flexibility, which are essential for the wing. The composite fuel tank with a capacity of 50L is an integral part of the wing and is inbuilt in the first third of the wing. The total fuel capacity is then 100L (2 x 50L). The wing is fitted with highly effective slotted flaps. Flaps and ailerons are made of carbon composite. The centrewing is welded of premium quality steel tubes (LCM-3).

All structural details like flap hinges, slots, mounting of Pitot tube, wingtips etc. are designed with regard to minimalize the airdrag.

The strength and behaviour of the wing structure were tested by simulation of various cases in the laboratory of the Czech Aeronautical Research Institute. Simply said, these tests have proven the wing is able to resist the g-load corresponding to +7,2 g.

Fuselage

The fuselage is a full-carbon composite shell braced with composite bulkheads of Nomex honeycomb and hardened foam. Its cross-section is elliptic with pure wing fillets and a spacious cockpit. Vertical tail fin is an integral part of the fuselage. Small windows installed on side walls behind the cockpit provide the crew with better view out and improve a lightning of the luggage compartment behind the crew. The engine compartment in front of the fuselage is separated from cockpit by the firewall, on which the engine mount and the nose gear are attached.

The weight of the whole fuselage, i.e. the carbon shell including bulkheads, is only 30 kg! During the load test, the fuselage had to resist the load of 3432 kg which was not a problem for its structure.

To increase a safety, the aircraft can be optionally equipped with the ballistic rescue system USH or Galaxy GRS, which is installed in the container at the bottom of the fuselage, under the luggage compartment behind the passenger´s seat bulkhead. In case of its activation, the rocket is fired through the small right side window and the aircraft descends on a parachute suspended on two straps, with the nose slightly tilted downward.

Tail unit

Classical cross-shaped tail unit is made of full-carbon composite. The tail fin is an integral part of the fuselage and so it gives the aircraft a dynamic look. Tapered horizontal tailplane consists of fix stabilizer with elevator rudder. Although the weight of stabilizer itself (without rudder) is 5,2 kg, its strength was proven by the load of 583 kg. The elevator rudder, which weighs only 900 grams, had to resist the load of 200,6 kg. Mass balance was then tested to incredible g-load 45 g. Also the vertical tail rudder resisted prescribed load of 266,6 kg.

Undercarriage

The undercarriage is three-wheel fix landing gear with steerable nose gear. The main gear is designed as a pair of composite leaf springs. The nose gear is combined of composite and duraluminium tube with aerodynamic cover, fitted with shock-absorbing rubber springs. The nose wheel size is 300x100 mm (4“). Electronic wheels on the main gear have a size of 350x120 mm (6“). Recommended inflation pressure of all tyres is 160 kPa.

Main wheels are fitted with hydraulic brakes, controlled by the brake lever cylinder installed on the control stick. The four-piston hydraulic brake has an excellent braking effect. All wheels are covered by aerodynamic spats.

The undercarriage had to resist a vertical load of 754 kg and a side-pull of 4.62 kN (471,5 kg) at the same time. The static drop test was performed from a height of 60 cm.

Controls

The aircraft is controlled by a classical control stick. The nose wheel is controlled by pedals and has a small turning radius. The steering of all rudders are doubled. Ailerons, elevator and flaps are steered by pushrods and levers, the vertical rudder is steered by stainless steel ropes. Ailerons have immediate response to controls. The aileron trim is standardly mechanical, but can be optionally electrical. The elevator trim is electrical. On the passenger´s side, it is possible to instal a second control stick, which is an advantage especially in pilot schools. The gripstick head can be fitted with control buttons of the trim, radio, autopilot or other optional functions.

Highly efficient slotted lift flaps have been developed using advanced computing methods. Flaps are electrically operated. The flaps controller is intuitive and does not allow movement of flaps in case actual airspeed is not appropriate for required position. When flaps move, the aircraft is automatically balanced, so that the pilot does not even notice a change of pitch moment.

All controls are designed the way to not disturb streamlined outline profile of the airframe. Important checking points of the steering have inspection holes covered by the transparent organic glass.

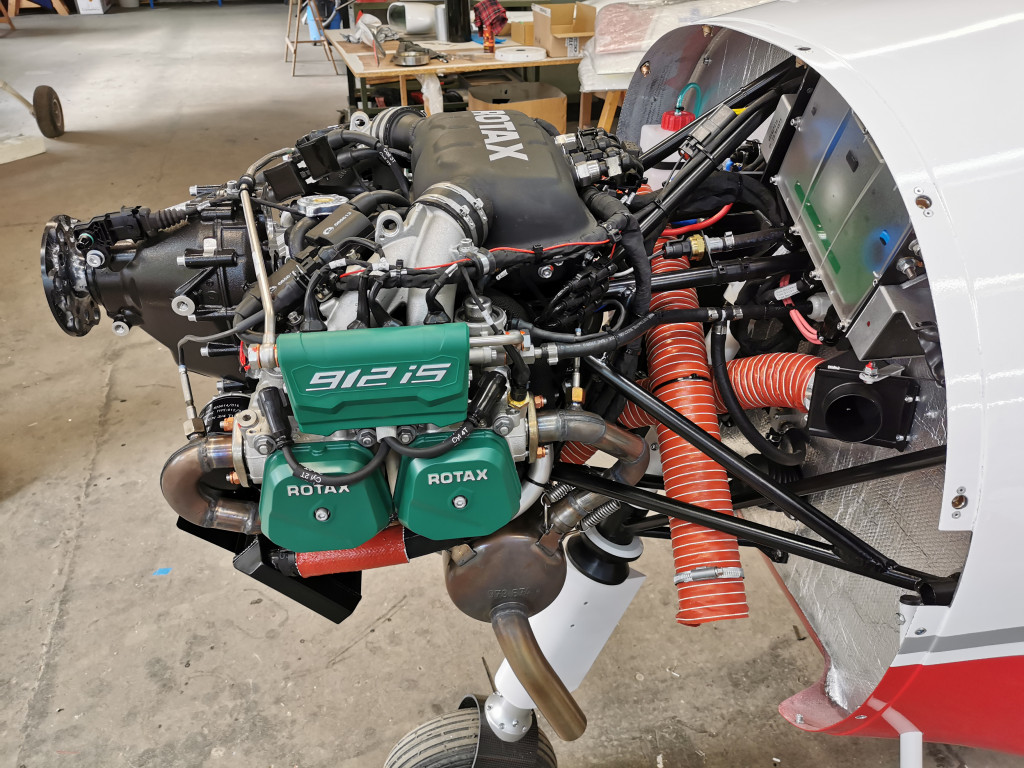

Propulsion unit

We offer only ROTAX engines in combination with full-composite propellers made by FITI Design company.

We use Rotax 912 ULS, iS Sport or 914 UL engine series. Operating temperature is maintained by the oil thermostat. The water thermostat is available as optional equipment. The engine mount is welded of high quality CrMo steel tubes. It´s strength was tested by the load of 1033 kg.

The propeller can be two- or three-bladed, fixed or adjustable on ground or in-flight. In-flight adjustable propeller is standardly controlled by the switch „TAKE-OFF/CRUISE“. Optionally it can be equipped with the constant speed control device, which maintains requested RPM stable disregarding actual flight mode and altitude.

We cooperate on testing and development of Fiti propellers and so these are developed the way to profit from flight characteristics of Atec airplanes and to reach the best Faeta´s performance and effective operation. This aircraft then becomes one of the fastest ultralight aircraft with exceptional performance and flight economy.

Fuel system

The fuel system consits of two wingtanks, each integrated inside one wing. Total fuel capacity is 100L (2 x 50L). Fuel tanks are fitted with a drain bowl and Curtis drain plug. The fuel distribution is assured by two independent circuits and fuel pumps (main and auxiliary) and monitored by the pressure gauge. To assure clear fuel flow, the system is fitted with several fuel filters. Our original installation enable safe solution of possible aeration of the fuel lines. Recommended fuel type is an usual motor unleaded petrol of minimum octane number RON 95, 97 (MOGAS EN228 Super or Super Plus) having max. 10% content of ethanol. When the fuel amount indicators light on, the fuel reserve is 5 liters. Fuel consumption is about 8 – 14 L/hr.

Instrumental equipment

A wide range of instrumental equipment allows to apply various alternative customized solutions. It is possible to instal basic instruments as well as the most advanced electronic systems for flight control and engine monitoring and various types of GPS. The aircraft can be equipped also with flight recorder, autopilot, various types of radios, transponders, ELT transmitters, anticollision systems etc. The USB and 12V plugs are a standard equipment. Static and dynamic pressure is taken from the Pitot tube installed underneath the wing. The dashboard is easily reachable from both seats and all controls are situated within a visual field of the pilot. A layout of instruments and controls is optional. We pay attention to keep their simplicity, well-arrangement, but also aesthetic effect.

Cockpit

The cockpit is all upholstered with a special fabric containing nanofibers which help to ensure its easier maintenance, high resistance, long lifetime and low weight. Upholstery is offered in various optional colour combinations. The seat is composed of carbon shell and two cushions. Their thickness can be customized if needed. Cushions are attached on velcro and so possible to exchange easily. The seat is adjustable front-/backward mechanically with a simple lever below the seat. However the weight of one seat is only 3,6 kg, it had to be tested for the load of 944 kg. Hi-quality branded safety belts are customized and produced by Sabelt. As an option, we offer the same type as being used by F1.

The crew enters the cockpit via front part of the wing, therefore there is no need to step on the seat. Pedals are mechanically adjustable in 3 positions. There are carbon armrests and storage net pockets on side walls of the cockpit. A spacious luggage compartment in the upper part of the cockpit behind the seats is accessible during the flight. Its capacity can be optionally increased by modifying the lower space behind the pilot´s seat. Two small ventilators inbuilt in the dashboard frame assure effective ventilation and heating. As to improve comfortability, we offer also heated seats. The part of the passenger´s floor is oblique in order to assure better ergonomy and so higher comfort also for legs.

Canopy

The canopy is made of organic glass (perspex) containing UV filter. It is fitted with small sliding windows on both sides. Small demisting fan inbuilt above the dashboard prevents it from fogging. The canopy opens up and backward. Electrical blocking system does not allow the engine start up in case the canopy is open or if not closed properly. Aerodynamic canopy hinge prevents the fuselage surface from abrasion.