Our three-year effort consisting of one year of preparing and two years of performing numerous load, strength and flight tests, processing of protocols, calculations and analysis, brought finally results. Both certificates are available to download here.

On 16th November, 2020, after passing long-lasting and difficult certification procedure, the Faeta NG finally achieved the Czech LAA and then also German DULV certificates for 600 kg MTOW in UL category. The ATEC 321 Faeta NG complies with Czech UL-2 and German LTF-UL regulations.

ATEC 321 Faeta NG met with all structural and safety requirements and successfully passed all necessary tests without problems.

At the beginning, aerodynamic analysis of the airframe must be processed as the first and the main background for next calculations, strenght analysis and other documents to be declared before the testing itself. Not only different loads, but also their distribution on individual parts, actuating forces, material strength and flutter resistance must be considered in calculations and tested for various cases (min-max. weights, various positions of the centre of gravity, speeds, wind conditions...). To reach the final resulted loads to be applied on each individual part during the tests, first the load coefficients specified by the legal regulations and safety factors must be included into the calculation. Finally, various models, samples, maquette of the cockpit and testing devices need to be produced and prepared for testing purposes.

The fact that the strength and safety requirements on such small ultralight airplane are really demanding is declared by several interesting facts and values, which we would like to present you.

So, what your plane needs to comply? Below is a choice of few examples of the most interesting or let´s say the most curious facts:

1/ The horizontal tail was loaded with a total weight of 583 kilograms and the rudders of the HT were loaded with 200,6 kg, even though the weight of the HT itself is only 5,2 kg and the rudder weight is even only 900 grams! The mass balance was loaded by the weight corresponding to the load factor of 45 G!

Each separated seat was loaded by 944 kg. The weight of the seat itself is only 3,6 kg!

The engine mount was loaded by 1033 kg in the gravity centre of the propulsion unit with a misalignment of the load by 17 cm out of its axis.

The fuselage was loaded by the total weight of 3432 kg.

The main gear had to resist the vertical load of 753,7 kg while pulling it sideward at the same time by the force of 4,62 kN (471,5 kg).

Drop test was carried out from a height of 60 cm above the ground.

During the tests of the wing-fuselage attachment, the fuselage was pulled by the force of 7,54 kN (769 kg).

Faeta NG does not have any speed limit up to the max. calculated flutter speed of 550 km/h and 3000 m of altitude.

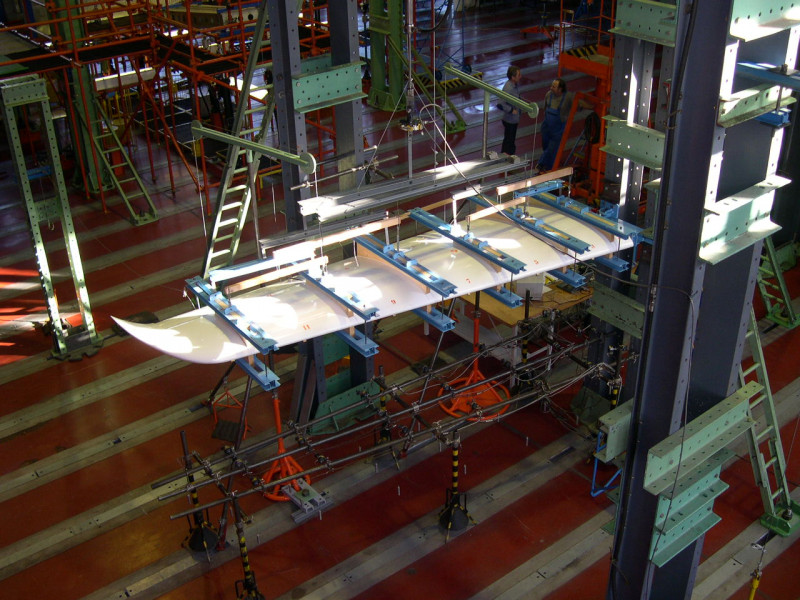

The wing was tested in the Czech aerospace research centre. It is being loaded by bending moments and tested for torsion. Limit values were analysed for each point of its envelope. The wing is able to resist the load equal to +7,2 g.

For testing purposes, it was necessary to produce a model of the fuselage and a number of corresponding testing devices.

Not only structural strength and load tests of the airframe itself were performed, but also the tests of rigidity and strength of the steering, mounting of the rescue system and seat belts or fixation of the luggage in the luggage compartment. In total 69 files with 548 documents containing protocoles, calculations, reports and analysis were processed, which means several thousands of pages completed as the certification background.

Published 14.12.2020